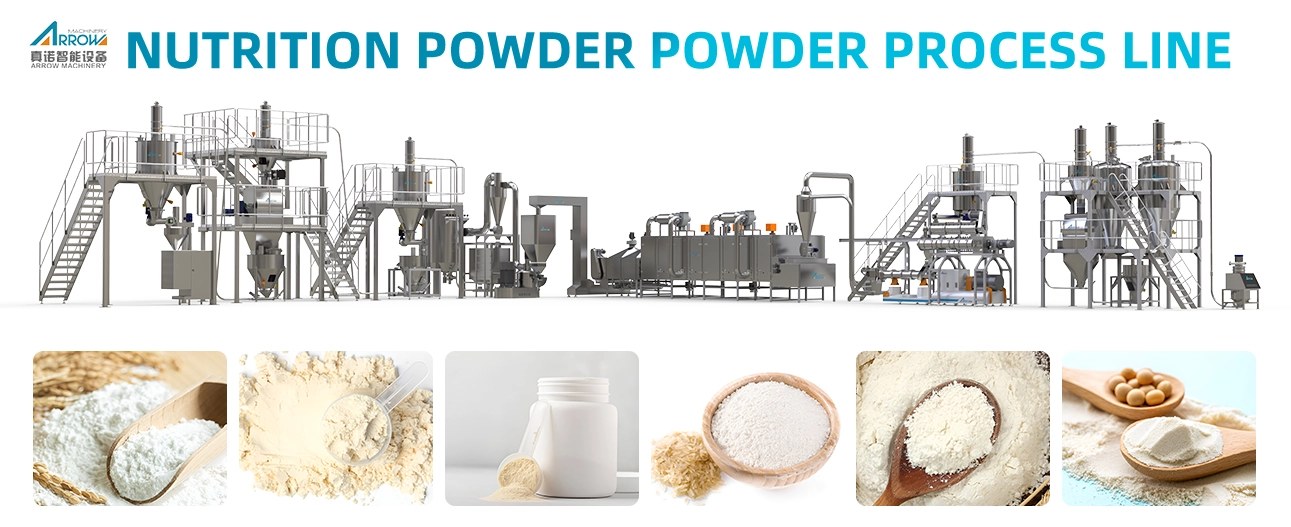

Product Description:

This process line uses rice,corn,beans and kinds of grains as raw materials.Through extruding ,inflating,drying,crushing and mixing ,it could produce many kinds of nutrition powder,such as baby rice powder,sesame paste,beans powder and so on.This line could finish all the process automatically from the feeding to the end.It has features of easy operation,without leak of powder dust,sanitation,saving energy and easy to add all kinds of raw materials and nutriment.

Flow Chart

Mixing → Extrusion → Drying → Cooling → Pulverizing

| Model | Screw Diameter | Power | Capacity |

| AYT65 | 20D | 37kW | 250-450kg/h |

| AYT78 | 20D | 55kW | 300-600kg/h |

| AYT98 | 20D | 110kW | 1-1.7t/h |

| AYT120 | 20D | 200kW | 1.5-3.5t/h |

| AYT135 | 20D | 280kW | 3-4.5t/h |

Features

Technical aspect: Shandong Arrow nutritional rice noodle production line adopts twin-screw extrusion technology to replace the new technology of traditional cooking rice noodle production. Traditional nutritional powder processing methods have many disadvantages such as low efficiency, problems, and small-scale production. In the nutritional powder food production line, the twin-screw extrusion technology makes up for all these deficiencies, which means that it can not only process grain raw materials, such as buckwheat, oats, etc. It can also produce more nutritious and healthy food that is beneficial to the body. All parts of our nutrition powder machine are made of food-grade stainless steel, which is very advanced and of high quality.

Operational aspects: Shandong Arrow nutritional rice noodle production line integrates mixing, cooking, ripening, puffing, sterilization and packaging, and does not require a boiler. The production process is simplified, efficient and environmentally friendly. This nutritional powder production line can automatically complete all processes from feeding to finishing, and can process and produce a large amount of nutritional powder in a short time. The nutrition powder machine always saves you a lot of working time and manpower, and improves work efficiency.

Packing & Shipping

Package: Wrap with film and secure with wooden pallet.

Transportation: Land or sea transport, LCL and FCL, provide flexible logistics solutions.

FAQ

Q: Are you a trade company or a manufacturer?

A: we are a manufacturer, welcome to visit our factory and check the machines.

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 20-35 days if the goods are not in stock, we could discuss before contract.

Q: Could you supply all the parameters about the machines?

A: Yes, we will supply all the parameters, price, layout drawing, factory design etc.

Q: How about the after-service?

A: We will send 1 engineer to the buyer’s factory for 7-14 days period installation and training to the operators.