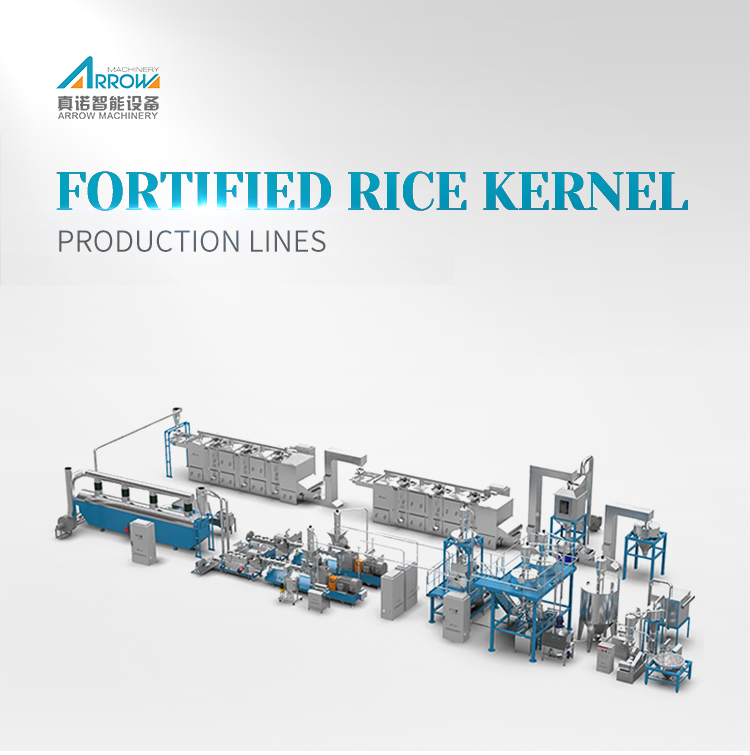

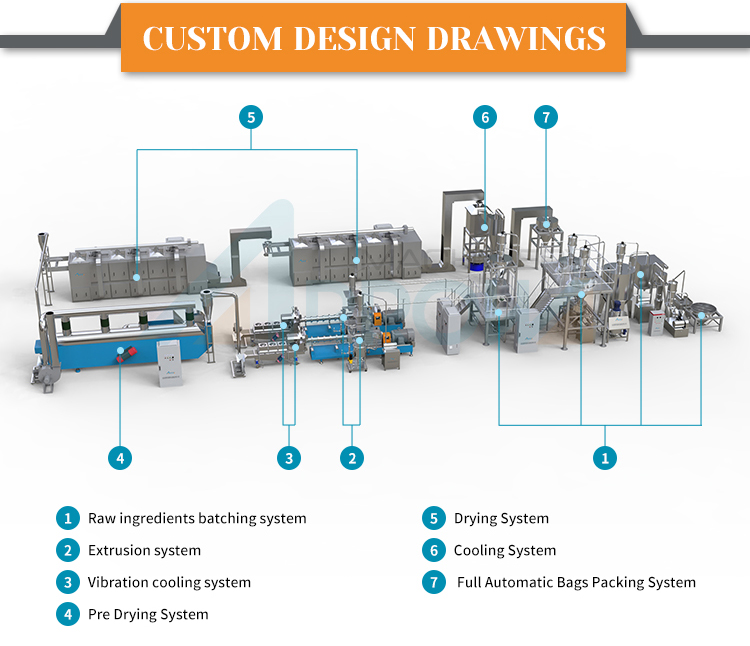

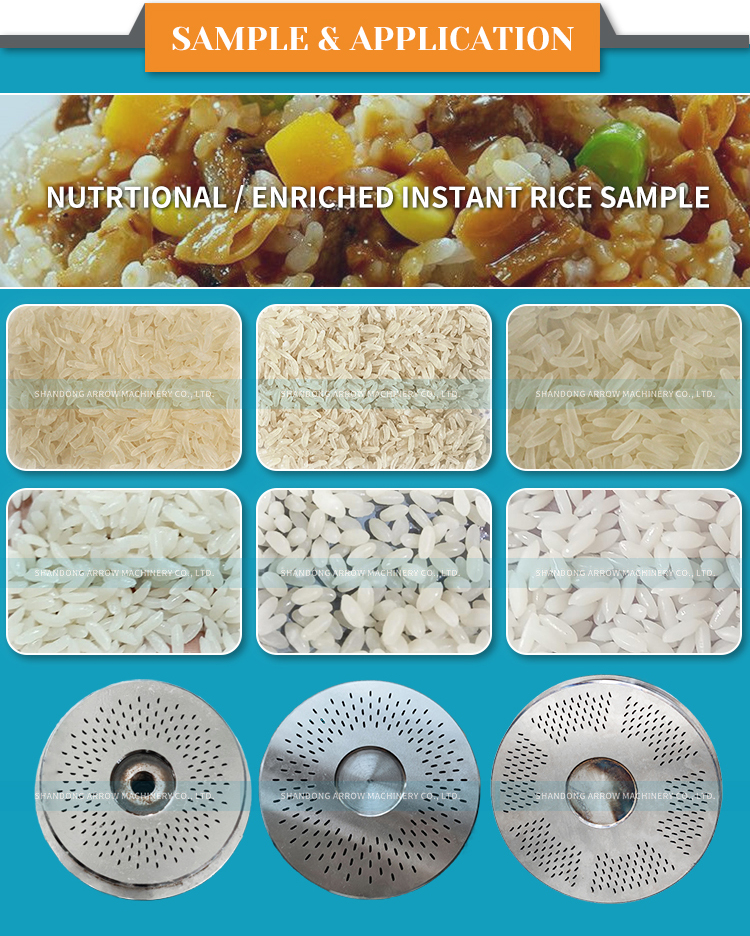

This nutrition/artificial fortified rice kernel production line is studied in concern with the loss of nutritional elements in the rice which is made by the traditional rice processing.Rice and its by adding additional nutritional nutrient components before extrusion cooking.Further,by this process,the broken rice bran can be reused.Process for making artificial rice grains,comprises mixing rice flour,water and oil and cooking them in extruder,forming into rice-grain shape,drying and cooling in low temperature.The technique makes it feasible to aviod the loss of nutrition.

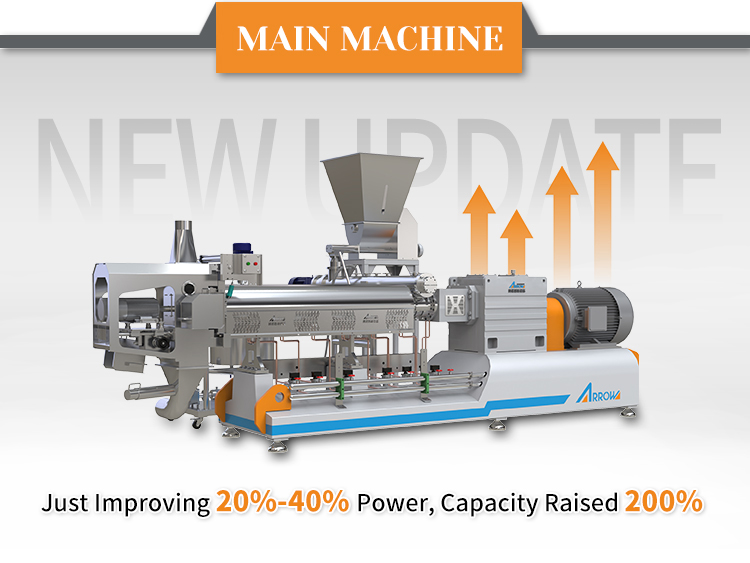

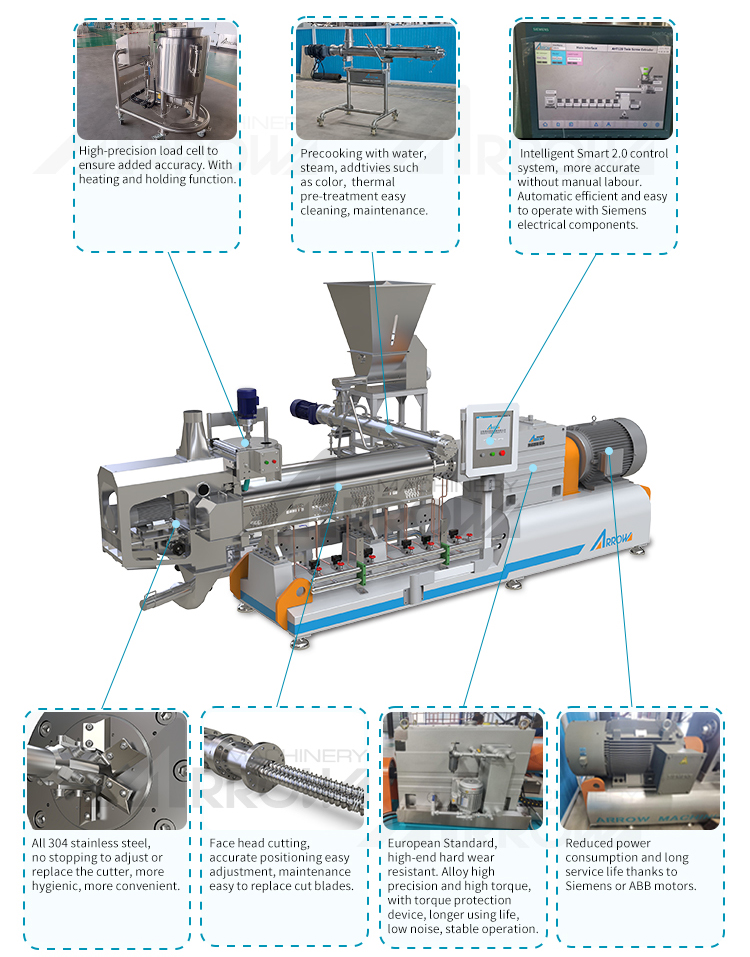

Product description: New technology can make up for the loss of micro-nutrients in traditional processing technology and strengthen the nutrtional value in rice food. The rice flour and broken rice are blended with vitamins and minerals,exreuded by extruder to retain vitamins and convenient.Leading the direction of future fast instant food products.Output:300-400kg/h, 600-800kg/h, 800-1000kg/h, 1500-2000kg/h.

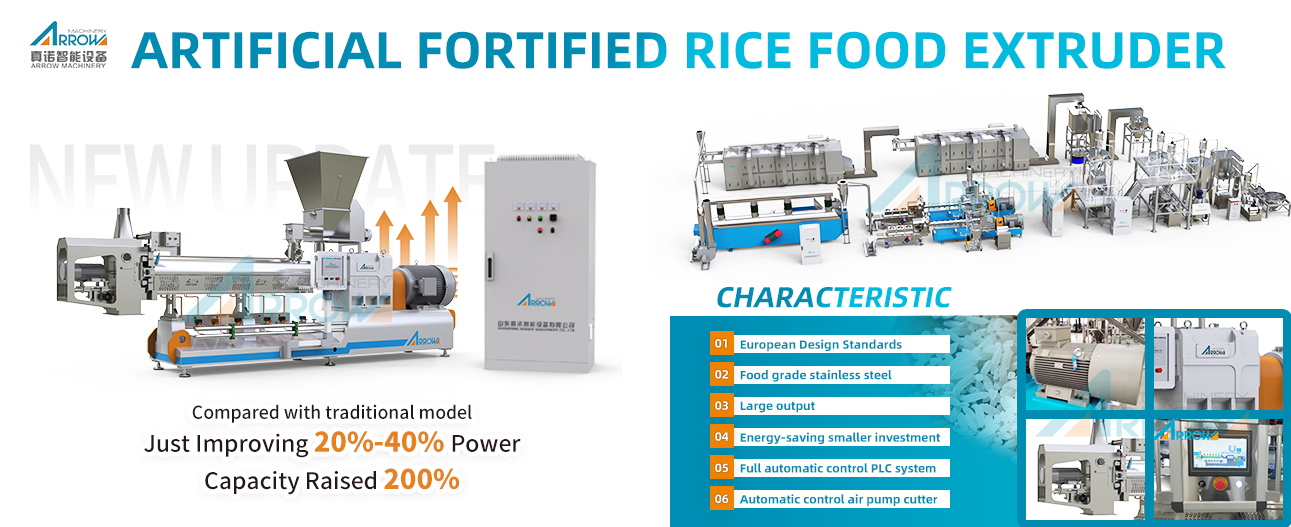

Artificial Fortified Rice Food Extruder

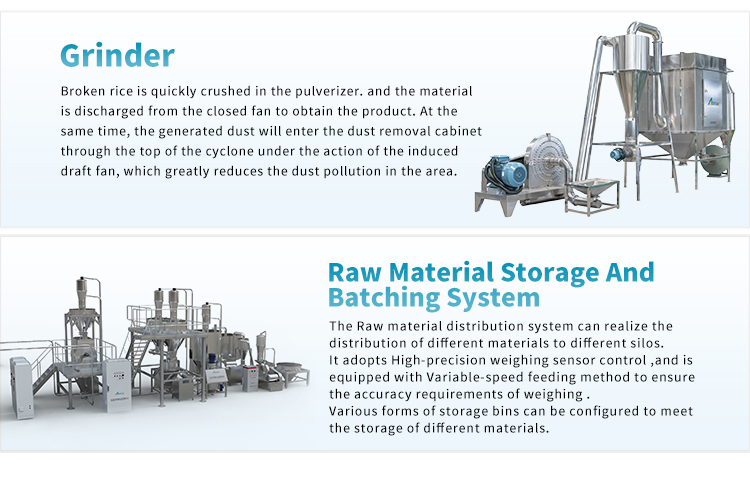

Rice is one of main food sources in the word. In rice processing, many valuable nutrients are lost during the process of whitening and polishing. We use twin-screw extrusion technology, take broken rice as raw material, finely milling and mixing with nutrients premix, after conditioning with steam and water, flour enter into the extruder to be regranulated, and finally dried. These extruded rice will be mixed with natural rice to get enriched nutrition rice.

Artificial Fortified Rice Food Extruder

Artificial Fortified Rice Food Extruder

Artificial Fortified Rice Food Extruder

Artificial Fortified Rice Food Extruder