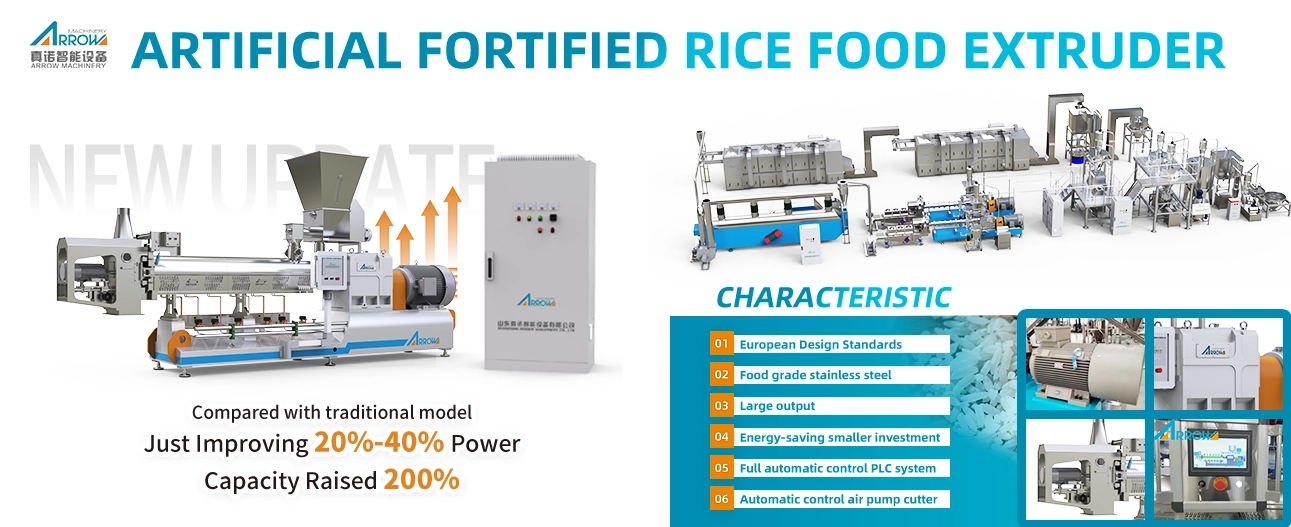

Product Description

This nutrition/artificial fortified rice kernel production line is studied in concern with the loss of nutritional elements in the rice which is made by the traditional rice processing.Rice and its by adding additional nutritional nutrient components before extrusion cooking.Further,by this process,the broken rice bran can be reused.Process for making artificial rice grains,comprises mixing rice flour,water and oil and cooking them in extruder,forming into rice-grain shape,drying and cooling in low temperature.The technique makes it feasible to aviod the loss of nutrition.

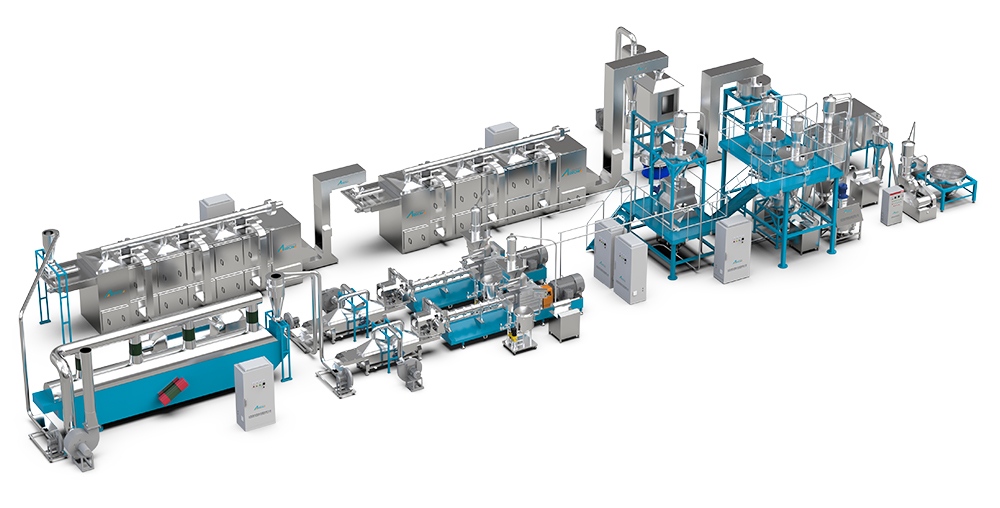

Process Flow

Ingredients – Mixing – Extrusion Curing – Pre-drying – Drying – Cooling – Packaging

Specification

| Model | Power | Capacity |

| AHE62 | 90-110kW | 200-800KG/H |

| AHE78 | 110-160kW | 300-1200KG/H |

| AHE90 | 160kW | 300-1500KG/H |

| AHE98 | 200-250kW | 800-2500KG/H |

Features

1. High degree of automation

2. Wide range of raw materials: can process various grain flours, such as corn, wheat, rice, millet, oats, konjac, yam, soybeans, mung beans, etc.

3. Can process rice into different shapes simply by changing the mold.

4. Automatic temperature control system makes temperature control more intuitive and parameters more accurate.

Our factory

All of the company’s equipment is independently designed and manufactured, holding numerous patents and widely recognized by customers both domestically and internationally. Shandong Arrow is committed to technological research and innovation in pet food engineering, aquatic/specialty feed factories, plant-based protein food engineering, and extrusion food engineering, including raw material processing and extrusion/gelatinization. With a complete turnkey system, we provide comprehensive project solutions tailored to specific client requirements, offering one-stop services including planning, R&D, design, civil engineering, manufacturing, logistics, installation, delivery, and training, ensuring rapid response to client needs.

FAQ