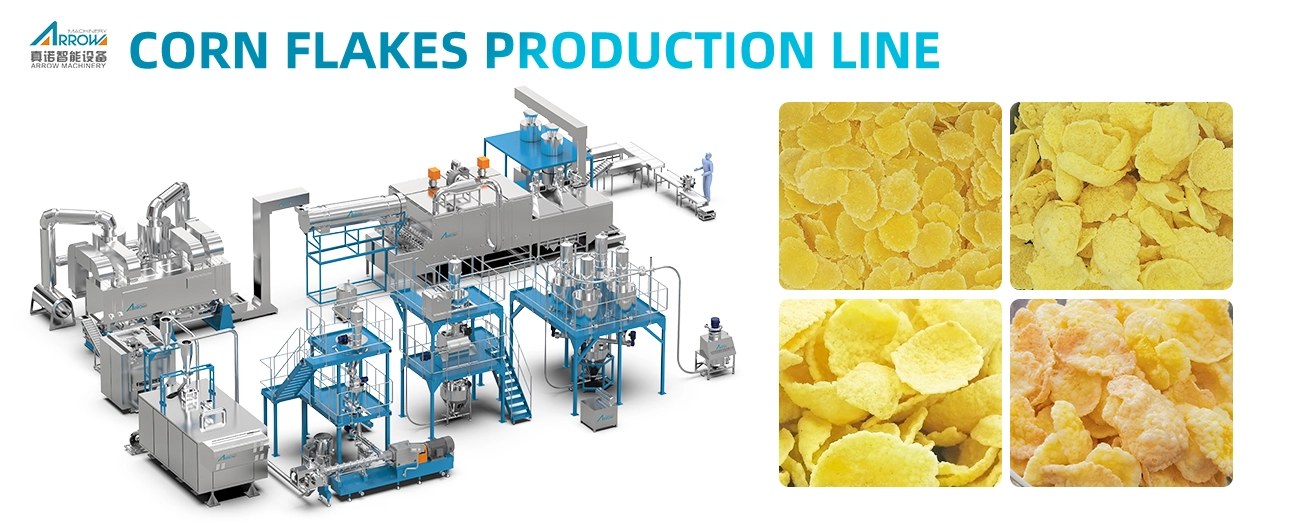

Product Description

Corn chips are a classic breakfast food, often eaten with milk and coffee, or as a casual snack. One outstanding characteristic of the corn flakes is that it contains abundant compound carbohydrates and dietary fibre, strengthens lots of microelements, such as vitamin and mineral, and also can be added with cocoa and suger, like honey and maltose. Use corn, wheat, oats grains as materials, after extruded by premium popular by different age consumers.Can be made into cornflakes, whole grain flakes, breakfast cereals, fruit-oat chips, multi-grains high fiber grain chips.. Arrow offers fully automated, modular twin-screw extruder production lines, scalable to various food applications.

Features

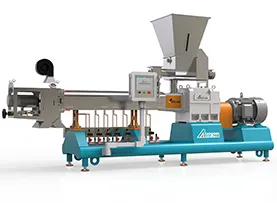

Automated operation: Corn flakes making machines are equipped with advanced automation technology, ensuring efficient and consistent production with minimal manual intervention.

Double Screw Extruder Equipped with Unique barrel and modular screw design, European standard design and materials, PLC control system, ensure the production much easier and convenient.

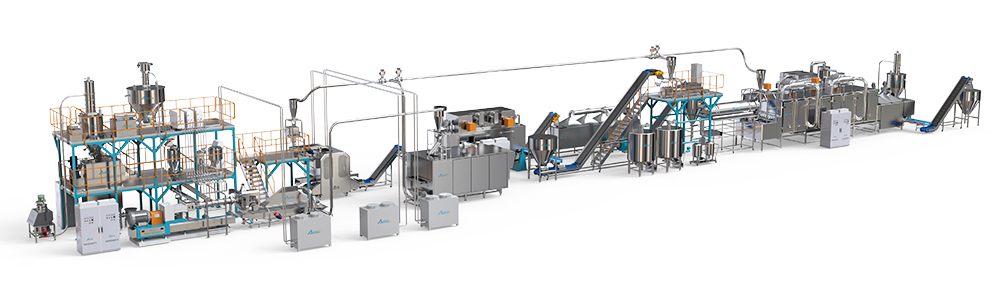

We provide High Capacity, Full Automatic and Whole Turn-key Project Solution for a Complete Cereals Plant.

Flow Chart

Weighing and Mixing—→Extruding—→Pre-Drying—→Flaking—→Toasting—→Cooling—→Coating—→Drying and Cooling

Specification

| Model | Power | Capacity |

| AYE65 | 37-75kW | 150-500KG/H |

| AYE78 | 55-90kW | 300-800KG/H |

| AYE98 | 110-160kW | 800-1200KG/H |

Packing & Shipping

1. We provide diverse packaging choices for secure product transportation, including plastic film wrapping or sturdy wooden crate protection, tailored to meet customer preferences and requirements.

2. We offer convenient transportation options, organizing land or sea shipments, whether LCL or FCL, to accommodate varying delivery preferences and provide flexible logistics solutions.

FAQ