Product Description

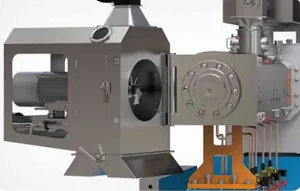

The working principle of a twin-screw extruder is as follows: Raw material enters through the feed inlet of the screw frame and is gradually propelled forward as the screw rotates. During this process, the raw material is carried to the compression zone below by the screw’s threaded grooves. In this zone, the threaded grooves gradually shallower, compressing the raw material and generating heat. Subsequently, the raw material enters the screw’s threaded mixing zone, where the threaded channels ensure uniform mixing and heating to a molten state. Afterward, the raw material enters the screw’s threaded conveying zone, where it is propelled forward by the screw, forming a continuous thread that extrudes the molten material.

Twin-screw extruders can more efficiently and uniformly mix molten plastics, resulting in better material properties and product quality. Furthermore, twin-screw extruders can typically handle a wider range of raw materials because their higher shear strength and heating capacity can accommodate different types and properties of raw materials.

Specification

| Model | Power | Capacity |

| AYE65 | 37-75kW | 150-500kg/h |

| AYE78 | 55-90kW | 300-800kg/h |

| AYE98 | 110-160kW | 800-1200kg/h |

Features

Updated rotary cutting system: Smooth cutting, low noise, and good product shape.

The patented upgraded gearbox delivers higher torque and stronger power.

Hygienic frame, safe and easy to clean

Larger space for easier operation