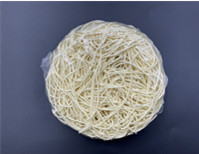

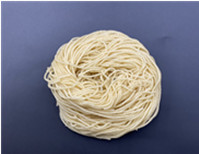

Product description: This Instant Noodles Production Line adopts a process completely different from fried instant noodles. It can eliminate the harm of fried food to human body.During production, flour, corn starch, and various vitamins are mixed evenly, and then extruded by a screw extruder. After passing through the cutting machine, steaming machine, cutting machine to cut a certain length of noodles into the dryer, after a long period of drying, the moisture will be reduced to less than 9%. Afterwards, the noodle cakes can be packed into bags through an automatic material sorting and packaging line. Instant noodles have very little oil content, taste smoother than instant noodles, and have the flavor of handmade noodles in noodle restaurants. The production line has a high degree of automation, reduces labor, avoids personnel contact, and improves food safety.

| model | installed power | output |

| AHE78H | 90KW | 600-750 KG/H |

| AHE90H | 160KW | 1200-1500 KG/H |

| AHE120H | 315 KW | 2500-3000 KG/H |

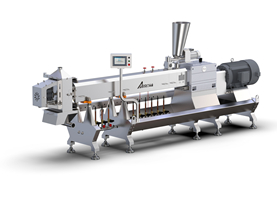

(1) Design: Developed by 3D software, analog simulation, and it has been tested by a computer automatically, in order to ensure

the accuracy of the design requirements.We have a professional and manufacturing industry to ensure the precision and coordination

of each component of the extruder, while maintaining stable processing and low noise.New Technology can make up for the loss of micro-nutrients in traditional processing technology and strengthen the nutritional value in rice food. The rice flour and broken rice are blended with vitamins and minerals ,extruded by extruder to retain vitamins and minerals. It has the characteristics of instant, nutritious and convenient. Leading the direction of future fast instant food products.

(2) Function: Modular function screw and barrel, humanized menu system, various applications. AYT double screw extruder for

advanced design concepts can meet different requirements.

(3) Materials: Precise food manufacturing technology and the best alloy metal materials ensure that the wear of the screw and

barrel is minimized, and the service life of the cable is longer.

(4) Application: We produce various kinds of food extrusion, such as vegetable protein, cereal flakes / breakfast cereals,

pellets, feed / animal feed, etc.

(5) After services: We provide a professional team of engineers to service installation and commissioning.

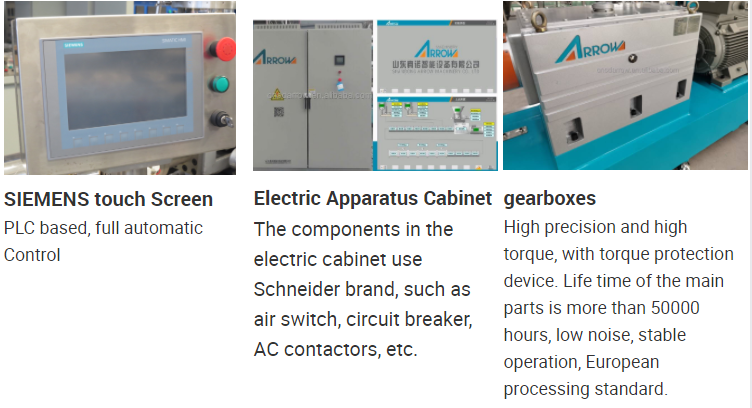

(1) Siemens Main Motor

(2) The screw adopts fully engaged model, designed by 3D design, CNC machining, smooth surface, high conjunction accuracy, and better self-cleaning function, changing parts flexibly.

(3) The screw and barrel adopt a combination modular structure, which can be assembled in any combination to meet different formulas and product requirements.