Cereal serves as a breakfast staple while its production requires exact engineering and sophisticated food processing methods and strict quality assurance procedures. The production of every box containing crunchy loops and honeyed flakes and multigrain stars requires a detailed process that transforms raw materials into finished products for store shelves. The production of cereal products depends on modern cereal production lines which maintain product consistency and safety while delivering innovative solutions throughout their manufacturing process.

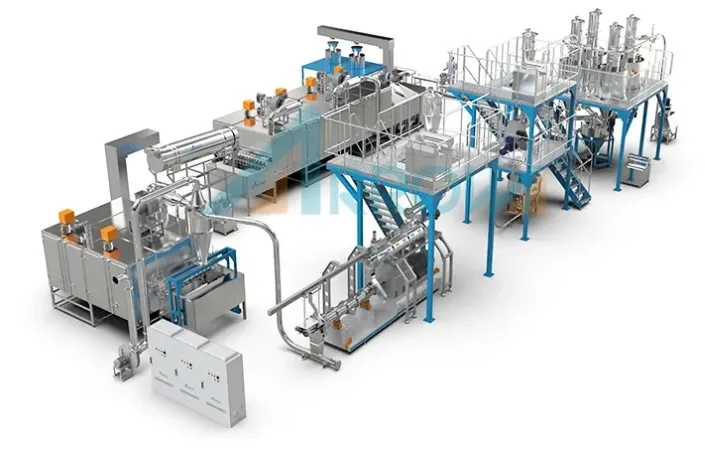

Shandong Arrow Machinery Co., Ltd. provides complete turnkey solutions to customers who need advanced solutions in this industry. The company operates as one of China’s top whole plant engineering solution providers since 1993 when it started delivering machinery to 1100 companies across 118 countries through its expertise in food technology based extrusion systems.

Understanding the Cereal Production Line Workflow

Raw Material Handling and Preparation

The production process begins with grains which serve as the initial materials. The selection process of raw materials followed by cleaning operations becomes essential for maintaining product consistency and ensuring hygiene standards. The production process uses corn and wheat and oats as materials which get processed through premium extruders to create nutritious products that appeal to various age groups.

The process of extrusion requires proper moisture levels which can be achieved by conditioning the materials. The process of conditioning grains leads to proper conditions for extruder expansion and textural development. The quality and efficiency of following processes depend directly on the uniformity of moisture content.

The raw material distribution process becomes more efficient through Arrow’s automated system which uses vacuum feeders and ribbon mixers and precision weighing sensors. The system achieves exact recipe execution through its high-precision weighing sensor control system and variable-speed feeding methods.

Extrusion and Cooking Technology

The extrusion system receives grains after they complete their conditioning process to become the central part of the cereal production line. This is where transformation happens.

The twin-screw extruder performs three functions by cooking the cereal base while simultaneously shaping it and expanding its size. The twin screw extruder line produces breakfast cereals which include choco rings and pillow center filled and fruit loops and crunch and cheerios. The machines provide high-shear mixing capabilities which create uniform dough structures and allow users to change dies for different shape production.

The Breakfast Cereals Production Line at Arrow Machinery operates with AYE65, AYE78 and AYE98 extruders which produce outputs ranging from 150 kg/h to 1200 kg/h. The new cutting system operates with minimal noise while producing products of excellent shape which maintains production stability when working with different ingredient combinations.

The systems require precise temperature and pressure management to maintain nutrient stability while achieving the desired food texture. The perfect equilibrium between these factors determines both product quality and nutritional content.

Drying, Coating, and Cooling Processes

The drying process follows extrusion to remove all remaining moisture from cereals. The drying process helps stop microbial development which results in longer product storage duration.

The hot air circulation chambers with humidity fans in advanced drying systems create uniform moisture removal through their hot air circulation system. The system features an independent hot-air circulation chamber with built-in circular air circulation for maximum drying efficiency. The system operates at reduced energy consumption. The dryers from Arrow feature modular construction which enables users to expand their capacity and perform maintenance operations with ease.

The process of flavoring follows syrup coating systems which consist of feeding systems and seasoning drums. The units provide multi-point spraying capabilities that increase the spraying area while sensors maintain stable coating volume between batches.

The product temperature reaches stability through cooling systems before packaging occurs. The process protects texture quality while making cereals ready for packaging by preventing both condensation and clumping.

Key Equipment in Modern Cereal Manufacturing

Role of Twin-Screw Extruders in Product Formation

Modern cereal production depends on twin-screw extruders because they offer flexible operation. The dual-shaft configuration of this design creates high-shear mixing that produces uniform dough structure which leads to consistent product texture.

The ability to swap out die heads on these machines enables fast product shape transitions between ring and ball forms and flake and star shapes which helps businesses develop new products. The extruders allow users to modify their formulas through adjustable screw designs and processing parameters.

The modular design of Arrow’s twin-screw extruders enables processors to adapt to changing market requirements through flexible configurations which enhance their operational agility and scalability.

Importance of Continuous Drying Systems

The process of drying involves both water removal and achieving equal drying results at high efficiency rates. The engineering of continuous drying systems enables operators to achieve precise moisture targets which protects products from decay while optimizing production capacity.

The heating box or exchange box operates at high efficiency levels because it supports multiple heating sources including steam and natural gas. The plate dryers from Arrow offer exact airflow and temperature management through their frequency inversion systems and separate drying compartments. The insulation doors of these units provide better thermal performance while enabling easier cleaning access.

The dryers operate as complete systems which maintain heat energy throughout the entire process from extrusion to drying.

Integration of Flavoring and Packaging Units

The final appeal of your cereal depends on coating and packaging methods which combine with flavor profile to create the complete product experience. Automated syrup coating systems apply sugar or seasonings with precision to produce uniform flavor results throughout big production runs.

High-speed packaging lines serve two essential purposes because they help organizations meet hygiene standards and maintain high production speeds. The combination of integrated systems in packaging operations minimizes human contact with products while enabling better product tracking.

Arrow provides complete systems solutions which start with extrusion and end at packaging to reduce the need for suppliers to work together.

Quality Control Measures in Cereal Production

In-Line Monitoring for Process Optimization

Modern cereal production depends on intelligent feedback systems which operate in the present moment. The system uses real-time sensors to track temperature and pressure and moisture levels throughout the production line.

The feedback loops allow for instant process modifications which help maintain product consistency. The control systems at Arrow enable operators to access operational data which guides their actions from start to finish of the process.

Post-Production Testing Protocols

The quality assessment process extends beyond production lines because post-production labs use physical attribute measurements of density and texture to verify products against established standards.

Food safety standards worldwide become enforceable through microbiological testing procedures. The Arrow equipment allows third-party quality assurance modules to integrate for complete data collection and audit trail functionality.

Hygiene Standards in Equipment Design

The foundation of food safety depends on designing systems with hygiene in mind. The stainless steel material used for all contact surfaces in Arrow equipment helps stop contamination from occurring.

The CIP (Clean-In-Place) system enables operators to perform quick equipment changes between production cycles while maintaining sanitary conditions. The equipment designs follow international food safety regulations through their compliance with ISO and CE certification standards.

Innovation Trends in Breakfast Cereal Processing Technology

Advancements in Extrusion Engineering Design

Processors require flexible equipment to handle changing consumer preferences. The modular design of extruder components enables quick equipment changes between different product and ingredient configurations.

Arrow uses R&D to enhance production speed while decreasing energy consumption by designing better screw shapes. The equipment from Arrow enables users to conduct both laboratory-based innovation and commercial-scale production.

Smart Automation and Digital Control Systems

The system provides real-time performance metric analysis through centralized PLC-based automation which enables both yield prediction and energy usage tracking.

The cereal production lines at Arrow use intelligent automation to achieve maximum uptime and efficient inventory control starting from grain reception through to finished product packaging.

Sustainable Manufacturing Solutions in Cereal Plants

Sustainability has evolved from being an optional practice into a fundamental requirement. The Arrow energy-efficient dryers operate to decrease carbon emissions during their production of each kilogram. The waste recycling systems at processing facilities extract important materials from waste streams.

Eco-friendly equipment design helps organizations achieve worldwide sustainability targets while generating long-term cost savings.

Customization Opportunities for Niche Cereal Products

Adapting Equipment for Multigrain or Functional Cereals

The growing demand for functional cereals requires flexible grain handling systems. The Arrow feeders operate as specialized feeders which maintain separate grain zones for millet and barley and gluten-free flours to prevent any cross-contamination.

The production process allows manufacturers to adjust extrusion parameters which enables them to create formulas with high fiber content and protein enrichment for health-oriented consumers.

Creating Unique Shapes, Textures, and Flavors

The tooling system functions as a key element which enables businesses to create unique products. Arrow offers customizable die sets which enable customers to produce animal-shaped cereals and star-shaped multigrain snacks according to their specific design needs.

The coating drum system enables product developers to create multiple flavor layers through chocolate glazing and vitamin spraying which results in unlimited creative possibilities.

Small-Batch Lines for R&D or Specialty Markets

The process of innovation starts with experimental testing. The pilot-scale lab extruders perform complete production tasks at reduced expenses and safety risks during product development testing.

The modular R&D lines from Arrow enable startups and specialty brands to launch distinctive products at speed while preserving industrial standards of precision.

FAQ

Q1: What raw materials can be used in a cereal production line?

A:The following ingredients can be used for product formulation: corn, rice, wheat flour, millet, sorghum, barley and gluten fiber.

Q2: How does twin-screw extrusion impact cereal quality?

A: The system provides uniform mixing and precise cooking and enables multiple shape options while maintaining nutritional values through its controlled operating parameters.

Q3: Can I produce multigrain cereals on the same line?

A: Specialized feeders help stop contamination between different feed materials while extrusion parameters can be adjusted to work with various grains and nutritional requirements.

Q4: What support does Arrow Machinery provide post-installation?

A: The company provides on-site training and remote diagnostic services and spare parts delivery and field debugging and continuous technical assistance throughout worldwide locations.

Q5: Are Arrow’s machines suitable for startups?

A: Absolutely. Their modular lines support small-batch R&D as well as commercial-scale production—ideal for startups entering the cereal market.