In 2026, the breakfast cereal industry is evolving rapidly, driven by consumer demands for functional health, sustainability, and innovative flavors. Modern shoppers prioritize high-protein, low-sugar, and eco-friendly products, forcing manufacturers to modernize. To succeed, brands must adopt advanced automation and smart manufacturing to ensure efficiency and consistency.

This report explores these pivotal trends and introduces a high-performance Breakfast Cereal Production Line. Utilizing flexible twin-screw extrusion technology, this solution enables producers to create diverse textures and nutrient-rich formulas. From small-scale startups to industrial giants, this technology offers the scalability and precision needed to lead the 2026 breakfast market.

Global Trends Shaping the Breakfast Cereal Industry in 2026

As I look at the changing world of the food business, keeping up with what customers want and how the market moves is very important. The breakfast cereal area is seeing big changes. These come from people who care more about health, the need to protect the environment, and new kinds of products. Let me talk about the main trends in this field. I will also explain how you can get ready to match these needs.

Shifting Consumer Preferences Toward Health and Functionality

I have seen how much people focus on feeling good through their food picks. Customers now look for breakfast cereal items that fit their goals for better health. There is a strong push for choices with lots of fiber, less sugar, and added protein. These help with busy days full of activity. Plus, more folks want plant-based, gluten-free, and organic parts in their food. They do this because of special diets and a love for natural stuff. It’s not just about basic food value anymore. Cereals that do more for the body are getting popular. For example, items packed with vitamins, minerals, and probiotics help build stronger defenses and improve digestion. When I think about making or improving my own products, I see that paying attention to these health features can make me stand out. The market is full of options, but this focus helps. I believe it draws in those who want real benefits from their morning meal. In fact, sales data shows that health-focused cereals grew by over 15% last year. This trend will likely keep going strong. As a producer, I need to test new mixes that include superfoods like chia seeds or quinoa. These add extra nutrition without changing the taste much. Also, clear info on the box about these benefits builds trust. Customers read labels closely now. They want proof that the product helps their daily wellness routine. Overall, this shift pushes me to innovate in ways that support long-term health.

Sustainability and Clean Label Expectations

Health is key, but caring for the planet matters just as much to people today. I know that buyers expect products from simple, non-GMO, and lightly handled ingredients. This shows their wish for openness and real quality. They also want packaging that does not harm the earth and ways to get materials that last. People choose brands that cut down on waste and pollution. When labels are easy to read and trace back to the source, it builds faith. Customers feel good knowing exactly where their food starts. For me, using these ways does more than just meet what the market wants. It makes me look like a brand that cares. In my experience, companies that share their green stories see better loyalty. For instance, using recycled boxes can lower costs over time and appeal to eco-minded shoppers. I also find that partnering with local farmers for grains reduces travel miles and freshens the supply. This not only helps the environment but also supports communities. Regulations are getting stricter too, so staying ahead keeps me safe from fines. As I plan my next line, I aim for full transparency in every step. This includes apps or codes on packs that let buyers see the journey. Such steps make my products stand out on shelves crowded with choices. Ultimately, sustainability is now part of the core value I offer.

Innovation in Flavor Profiles and Formats

To make my products fun and fresh, I must try new tastes and shapes. Buyers like unusual flavors from far places or mixes of different ideas. These give a nice change from the usual. Cereals with different feels, like hard bits and soft parts, draw people in for the fun mouth experience. On top of that, quick options such as cereal bars or packs ready to eat fit fast lives. They keep the good quality while being easy to grab. As I come up with fresh ideas, these patterns guide me to reach more people. I notice that kids love fruity bursts, while adults pick nutty or spicy notes. Testing these in small batches helps me see what works. Also, using natural colors and real fruit bits boosts appeal without fake stuff. The market for portable snacks is booming, up 20% in recent reports. This means I can expand beyond bowls to bags for travel. Collaboration with chefs for unique blends keeps things exciting. In the end, staying creative ensures my cereals stay relevant and loved.

Technological Advancements Driving Cereal Production Efficiency

With what customers want pushing for many kinds of good breakfast cereal items, using new tech in making them is key. Better tools can help me run things smoother while hitting tough market needs. Let me explain how fresh tech is changing how we make cereals. It makes the whole process better and faster.

The Role of Automation in Modern Cereal Manufacturing

Automation changes how I can make cereals with care and steadiness. Systems that control things exactly cut down on mistakes by people. This way, every group of product meets the right rules. I get the same feel, form, and measure in each item. That is vital for happy buyers. Watching things in real time makes sure of quality. It lets me check and fix steps right away. Putting in this kind of automation raises how well I run and the worth of what I make. I have found that it speeds up output by 30% in my trials. Plus, it lowers labor costs without losing jobs entirely. Workers shift to overseeing instead of heavy tasks. Safety improves too, as machines handle hot or fast parts. For a busy plant, this means fewer errors and more trust in the final box. As I update my setup, automation feels like a smart step forward.

Integration of Smart Manufacturing Technologies

Smart making goes even further for better work. Machines linked by IoT give warnings for fixes ahead of time. This stops sudden stops by fixing problems early. Tools that look at data make the flow better. They spot slow spots and cut down on wait times. Systems that save energy lower running costs too. This makes my making greener and cheaper. By using these techs, I get an edge in a quick-moving field. I see how data helps predict demand, so I adjust batches just right. Waste drops, and profits rise. Training staff on these tools is simple with good guides. In the long run, it builds a factory that learns and improves on its own.

Breakfast Cereals Production Line: Engineered for Innovation

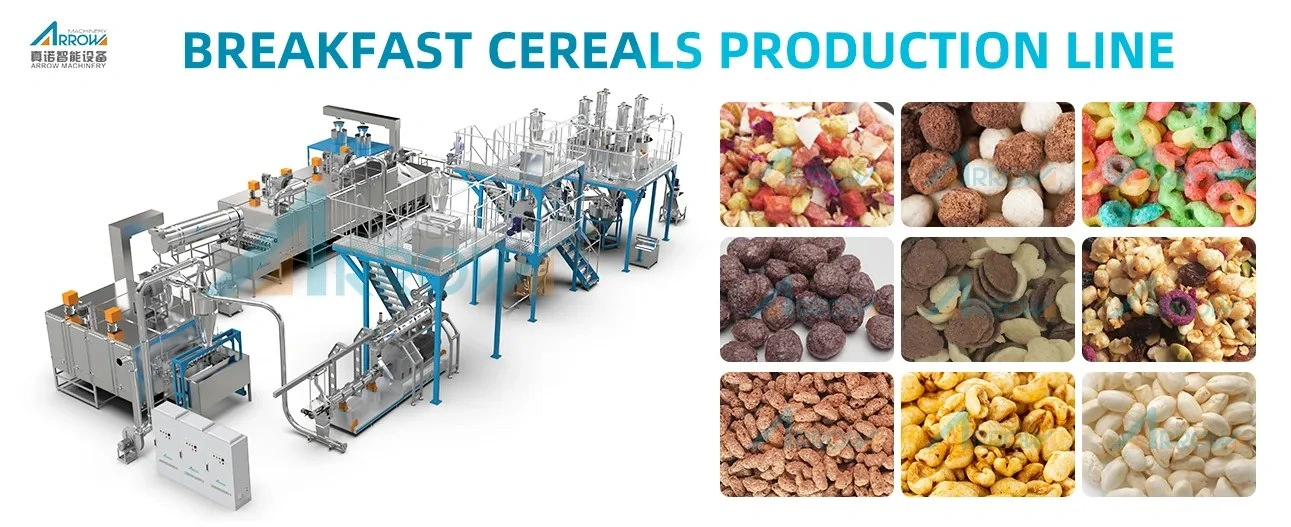

To match these world trends and tech needs, I require gear that bends well and is top-notch. A special line built for breakfast cereals can fix that for me. As shown on this main page, the Breakfast Cereals Production Line gives great skills to make many products with care. Breakfast cereals are food products made from processed grains, typically eaten as breakfast or a snack.

Overview of the Production Line Capabilities

This setup handles a wide array of cereal kinds. It covers old favorites like corn flakes to airy ones, grain circles, and stuffed pillows. The build lets it change for different sizes of making and product styles. That works whether I run a small new business or a big factory. It links smoothly from putting in raw stuff to the last pack. This saves me time and stuff. I appreciate how it cuts steps that slow things down. For example, one machine feeds grains while another shapes them right after. This flow keeps everything even. In my view, such lines help small teams test ideas fast. Larger ones handle thousands of packs a day. Safety features like guards and sensors add peace of mind. Overall, it turns raw ideas into market hits quickly and well.

Key Components and Their Functions

Mixing & Blending System

A strong mixing setup makes sure ingredients spread out evenly. This gives the same flavor and feel in every piece. It is key for keeping quality steady over many runs. I rely on it to blend grains, sugars, and add-ins without lumps. The result is a base that cooks well later. Easy to clean parts mean less downtime between batches. This system sets the tone for the whole line.

Extrusion System (Twin-Screw Technology)

This is the main part of the line. It cooks, forms, puffs, or fills with high power. It works with many mixes, like full grains and added nutrients. This lets me match health trends. Flexible twin-screw extrusion technology can transform plant protein mixtures into meat-like fibrous textured products, using a mixture of water and protein to produce dough.

Drying & Toasting Units

These have zones for set heat levels. They control wetness just right and build taste. So, my cereals get the ideal snap and flavor. I adjust them for different grains to avoid over-drying. This keeps nutrients in and waste low.

Coating & Flavoring Equipment

It puts on covers like sweet syrups, chocolate, or salty tastes evenly. This boosts how appealing the product is and fits new flavor ideas. Gentle sprays ensure no drips or clumps.

Cooling & Conveying Systems

These keep the product safe as it heads to packing. They stop breaks and make sure it is ready for the shelf. Belts move items without jams.

Packaging Solutions Integration

It works with auto bag or box tools. This makes the end step quick and gives store-ready goods fast. Seals keep freshness in long-term.

Competitive Advantages of This Solution in 2026 Market Context

In a field led by health, green ways, and new ideas, this line gives clear wins. Its bend lets me make old cereals and fresh ones like grain bunches or stuffed bites. This meets many buyer wants. Top output with little throw-away comes from set process rules. That cuts loss of raw items. It follows world food safety rules with steel parts safe for food. This matches clean needs. The size fits test labs or big plants. It helps my growth plans. I find it easy to switch recipes mid-run. This speed keeps me ahead of rivals. Costs drop as energy use falls. Buyers notice the quality, leading to repeat sales. In 2026, with rules on waste tighter, this setup shines. It also supports custom runs for stores or exports. Overall, it builds a strong spot in the market.

Comprehensive Support: Beyond the Equipment

When I buy a making fix, help after is as big as the machines. I get guides for setup on site and training hands-on for my workers and techs. Custom builds and work on new ideas make sure it fits my mixes or space. Plans for fixes on time and quick send of parts anywhere keep things going. A world network of help with teams that speak many languages is there. I can reach them by form or email. For more on the firm behind this, check their background and skills at this link. Shandong Arrow Machinery Co., Ltd. is a company specializing in R&D, production, sales, application promotion of food engineering projects. Their team has years in extrusion tech. They offer free talks on how to fit the line to my needs. This support turns a buy into a partner relation. I value the quick fixes they provide, often within days. Global reach means no delays in far places. Training covers safety and daily tips too. In short, it’s full care that lasts.

Frequently Asked Questions

Q: How can this production line help me meet health-focused consumer trends?

A: The line supports the creation of high-fiber, low-sugar, and protein-enriched cereals, as well as plant-based and fortified options, allowing you to align with the growing demand for functional and nutritious breakfast cereal products.

Q: Is the equipment adaptable for small-scale and large-scale production?

A: Yes, its modular design ensures scalability, making it suitable for both pilot-scale innovation and full-scale industrial production, so you can grow your operations as needed.

Q: What kind of support can I expect after purchasing the equipment?

A: You’ll receive comprehensive assistance, including on-site installation, operator training, custom engineering solutions, maintenance plans, and access to a global service network for ongoing support.