Product Introduction

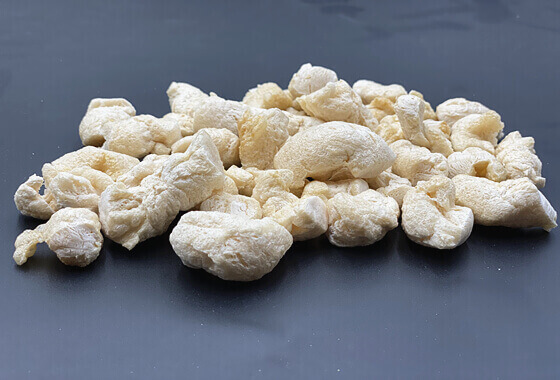

This production line is specifically designed for producing a variety of delicious and crispy fried pasta snacks. Using high-quality wheat flour and grain flour as main ingredients, it employs a fully automated process to sequentially complete core steps such as dough mixing, dough pressing, cutting, frying, oil removal, seasoning, and cooling, ultimately producing golden-yellow, flavorful snacks. The production line combines high efficiency, stability, and flexibility, and its products are widely used in the snack food and catering industries.

Flow Chart

Kneading dough → Pressing dough → Cutting and shaping → Frying and puffing → Degreasing → Seasoning → Cooling

Features & Advantages

1. Flexible Process and Strong Adaptability: The production line adopts a modular design, allowing for flexible adjustments to the process based on different product formulas (such as the addition of grains and seasonings) and final shapes (such as strips, blocks, and twisted shapes), quickly responding to diverse market demands.

2. Rich and Diverse Product Forms: By changing specialized cutting molds and adjusting parameters, the same production line can stably produce puffed foods of various shapes and specifications, meeting customers’ production needs for different product series.

3. High Efficiency, Stability, and High Degree of Automation: From raw material mixing to finished product cooling, fully automated continuous production is achieved, ensuring stable capacity, significantly reducing manual intervention, ensuring consistent product quality, and improving production efficiency.

4. Precise Control, Balancing Quality and Energy Saving: Equipped with an intelligent control system, it can precisely control key parameters such as dough mixing time, dough thickness, frying temperature and time, oil removal efficiency, and seasoning uniformity. This not only ensures optimal crispness, color, and oil content of the product but also achieves low energy consumption.

5. High return on investment and easy operation: The entire production line is compact in design, has low energy consumption, and moderate output, featuring relatively low investment costs and quick turnaround time. The user interface is friendly, easy to learn, and allows for rapid and stable production.

6. Safe and hygienic, meeting standards: The main contact parts of the equipment are made of food-grade stainless steel, designed for easy cleaning and maintenance, and comply with food safety production standards, ensuring a hygienic production environment and product safety.

Customer Cases

FAQ

Q: What is the delivery time for the production line?

A: Delivery time depends on the specific configuration and level of automation of the production line. For a standard medium-sized production line, the typical delivery time is 30-45 working days. We will provide you with a precise delivery schedule based on the final confirmed production line plan.

Q: Do you provide installation and commissioning services?

A: Yes. For the purchase of the entire production line, we provide professional engineers for on-site installation and commissioning services. The standard installation and commissioning cycle is approximately 1-2 weeks. We also provide detailed operation manuals, maintenance guides, and remote video support to ensure your team can smoothly master operation and basic maintenance.

Q: What is the warranty period for the equipment? What does the warranty cover?

A: A one-year warranty is provided for the core components of the entire machine (such as the motor, reducer, control system, etc.). For vulnerable parts (such as special cutters, conveyor belts, some seals, etc.), we will clearly list them in the contract and provide reasonable spare parts recommendations. Thanks to the modular design, most worn parts can be replaced individually without replacing the entire unit, effectively reducing long-term maintenance costs.

Q: What is the energy consumption of this production line?

A: This production line is designed with energy conservation in mind. For example, the frying section uses efficient heating and heat preservation technology, and the conveying system uses frequency conversion control to reduce operating energy consumption. We can provide estimated energy consumption data for your reference based on your specific production capacity requirements.

Q: Is it complicated to change production if I want to produce products with different shapes or flavors?

A: Changeover is very convenient. Simply change the shape of the cutting molds to produce products with different appearances. The seasoning system (such as spraying powder, mixing powder) can be easily adjusted according to the recipe. We will assist you in testing different recipes during the commissioning phase and provide corresponding process parameter suggestions.

Q: What is the production line’s capacity?

A: Capacity depends on the model of the production line and the specific specifications of the product (size, thickness). Our production lines are designed with multiple capacity levels, such as 50 kg, 100 kg, 200 kg per hour, or higher. Please inform us of your target output, and we will recommend the most suitable model for you.