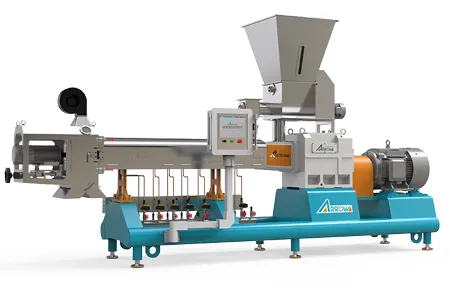

Product Introduction

This production line utilizes twin-screw extrusion puffing technology to replace traditional methods of producing rice crackers and similar products. The line integrates mixing, cooking, puffing, and shaping into a single process, eliminating the need for a boiler. This simplified, efficient, environmentally friendly, and low-carbon production process allows for the use of raw materials such as rice flour, corn flour, and wheat flour, as well as mixtures thereof. Shapes can be altered simply by changing the molds, forming machine, and cutting machine, resulting in shapes such as strips, diamond-shaped sheets, wavy sheets, pillow shapes, and horn shapes.

Technical Parameter:

| Model | Power | Capacity |

| AYE65 | 37-75kW | 150-500kg/h |

| AYE78 | 55-90kW | 300-800kg/h |

| AYE98 | 110-160kW | 800-1200kg/h |

Flow Chart

Mixing → Extrusion → Shaping → Separation → Frying → Seasoning

Line Features & Advantages

1. The twin-screw extruder features a unique barrel and modular screw design, adopting European standard design and materials, and a PLC control system to ensure more convenient and efficient production.

2. Raw materials are mainly grain flours, such as corn flour, wheat flour, rice flour, and oat flour.

3. Equipped with an automatic continuous frying machine, featuring an oil circulation system, automatic oil filling, an oil filtration system, and automatic online oil cleaning. Frying time and temperature can be adjusted for different products.

4. Multiple capacity solutions are available, ranging from 200 kg/hour to 2000 kg/hour.

Case

FAQ

Q: What is the lead time for the production line?

A: The lead time depends on the specific configuration and level of automation of the production line. For a standard medium-sized production line, the typical lead time is 30-45 working days. We will provide you with a precise delivery schedule based on the final confirmed production line plan.

Q: Do you provide installation and commissioning services?

A: Yes. For the purchase of the entire production line, we provide professional engineers for on-site installation and commissioning services. The standard installation and commissioning cycle is approximately 1-2 weeks. We also provide detailed operation manuals, maintenance guides, and remote video support to ensure your team can smoothly master operation and basic maintenance.

Q: Is the conversion complicated if I want to produce products of different shapes or flavors?

A: Conversion is very convenient. Simply change the shape of the cutting die to produce products with different appearances.

Q: What is the production line’s capacity?

A: The capacity depends on the model of the production line and the specific specifications of the product (size, thickness). Our production lines are designed with multiple capacity levels, such as 50 kg, 100 kg, 200 kg per hour, or higher. Please tell us your target output, and we will recommend the most suitable model for you.