Tel: 0086-531-83146566

E-mail: info@arrowextrusion.com

Tel: 0086-531-83146566

E-mail: info@arrowextrusion.com

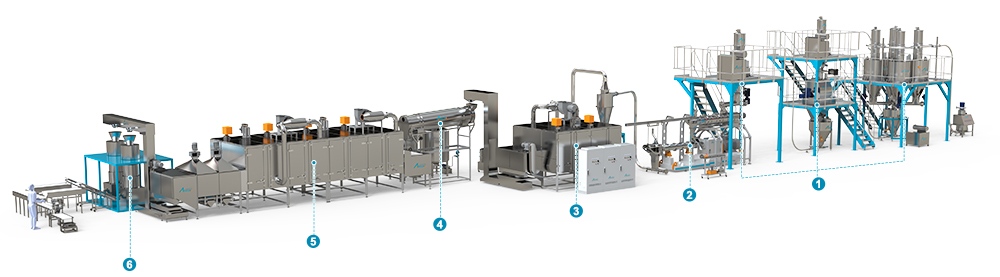

①Ingredient Mixing②Extrusion and Expansion③Pre-Drying④Coating⑤Drying and Cooling⑥Packaging