Nutritional powder is a convenient dietary supplement suitable for people with different needs and has a wide range of applications in various fields. In recent years, the nutritional powder market has expanded rapidly. In 2022, the global market size has exceeded US$50 billion, and it is expected to exceed US$80 billion by 2030, with a compound annual growth rate (CAGR) of about 7.5%.

Nutritional powder products can be mainly divided into: nutritional meal replacement powder, infant rice cereal, and pregelatinized starch. The main raw materials are rice, wheat, yam, red bean powder, etc. and starch raw materials.

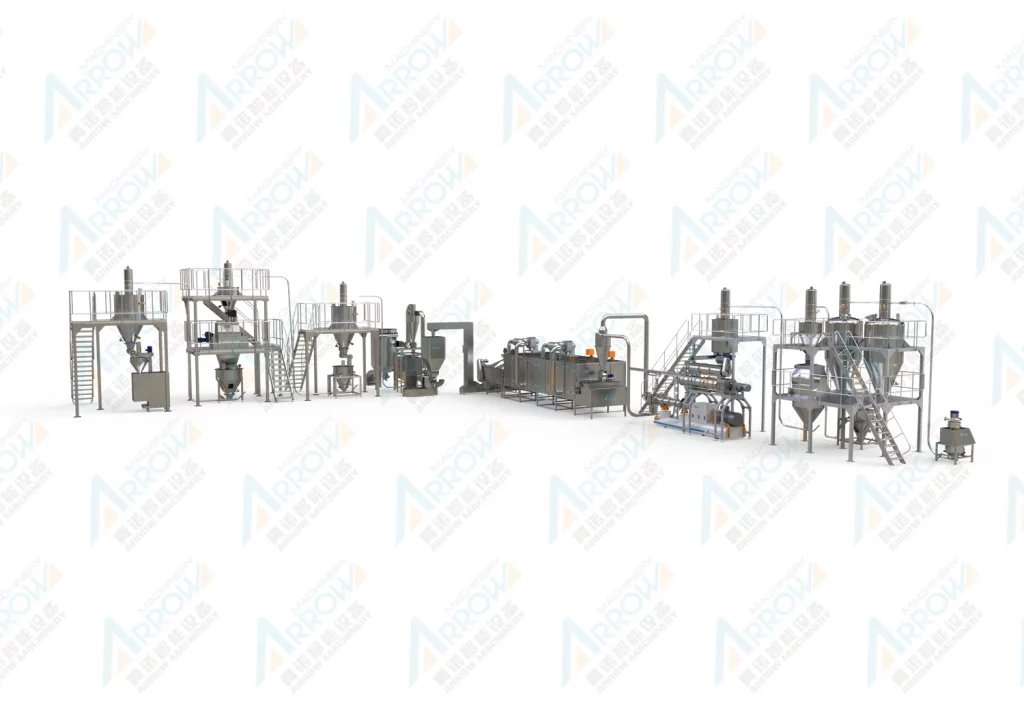

Feeding system: This part can be equipped with one or more storage bins for storing different kinds of raw materials. The raw materials are transported by vacuum negative pressure through the feeding station, and different raw materials are transported to the corresponding storage bin for subsequent use.

Batching system: There is a conveying auger under the storage bin, and a batching scale is installed directly below the auger. According to the weight of different materials pre-set in the formula, it is automatically weighed.

Mixing system: It is equipped with a high-efficiency paddle mixer, which transports the materials in the batching scale to the mixer for automatic mixing through negative pressure air delivery.

Extrusion system: The mixed raw materials are sent into the weightless feeder through negative pressure air, and then quantitatively enter the twin-screw extrusion extruder through PLC control. At the same time, the liquid feeder injects a certain amount of water. Under the extrusion of the twin screw, high temperature and high pressure, the production of the product is completed.

Drying system: The extruded product needs to be dried to a moisture content of less than 10% to facilitate long-term subsequent crushing.

Crushing system: Fully automatic crushing system, which can crush different products according to requirements.

Advantages of the production line of nutritional meal replacement powder

1.Different production lines can be customized according to customer requirements so that customers can better produce different products.

2.Adopting the latest automatic control system, the energy utilization efficiency is high, and unnecessary energy loss is effectively reduced.

3.Almost zero waste emissions are achieved during the production process, which is in line with the concept of green development of modern industry.

4.Every component of the equipment will undergo strict testing to ensure that it meets or even exceeds national standards.

Company introduction

Shandong Arrow Machinery Co., Ltd. serves more than 1,100 customer factories around the world, and its products are sold to 118 countries and regions. It has a team with more than 30 years of industry experience. The company has won many honorary titles such as “3A-level contract-abiding and trustworthy enterprise” and “high-tech enterprise”.

The company has many product R&D personnel and a complete and independent “food extrusion technology R&D center”, which can provide food process research, formula development and application for customers. The company focuses on the R&D and stable production of new products. It conducts product R&D many times a year and develops new products with customers. The company has reached cooperation with many universities and research institutes to work together for the development of new products.