| Contents | Parameter |

| Dimensions | 3300*1000*1800mm |

| application |

For science, teaching, research and experiment |

| Applicable raw materials | Rice, corn, wheat, soybeans, peanuts, peas, chickpeas, sunflower seeds, oats, buckwheat, potatoes, starch, vegetables, dates, sea buckthorn and other mixed powdery raw materials. |

| Products that can be produced | Plant-based meat products, instant rice noodles, puffed foods, snack foods, breakfast cereals, nutritional powder and pet feed products, etc. |

| Motor brand | Siemens inverter motor |

| output | 10-50KG/H |

| main motor power |

18.5kw |

1 Features:

The extruder is mainly composed of screw extrusion system, transmission system, feeding system, heating system, rotary cutting system and frame.

The design adopts three-dimensional software three-dimensional design, simulation simulation, and coordination testing are all automatically completed by the computer to ensure the design accuracy requirements.

2 Extrusion electromechanical devices and electrical control:

PLC chooses the internationally well-known Siemens brand, PLC central control, fast speed and stable performance. The original parts in the electrical cabinet are of Schneider brand, such as MCBs, circuit breakers, AC contactors, etc.

3 Mechanical structure

Gear box and gear:

Gearbox is a hard-toothed gear transmission designed specifically for co-rotating parallel twin-screw extruders based on the design concepts and methods of German and Austrian counterparts. The gears and shaft materials are made of high-quality alloy steel, and the tooth profile and helix are modified at the same time to ensure the perfect meshing of the gears under load, so as to achieve low noise and high efficiency.

Bearing:

bearings are generally selected from well-known Asian brands, such as IKO, ZWZ, LYC, etc.

Motor:

The main motor is selected from Siemens brand. The higher efficiency level reduces energy consumption and directly enables users to save costs! Higher protection level (IP55) ensures safe and reliable use by customers!

Feeder:

Twin-screw volumetric feeder is widely applicable to various materials, including powdery, fibrous and flake materials with poor fluidity.

Extrusion cavity:

The cavity is a combined building block structure, and the length of each cavity is 4D, which can be increased or decreased according to needs; the internal heating and cooling medium circulation in the cavity adopts the optimized design, which can ensure that the temperature control is sensitive and the temperature difference between inside and outside is small; each cavity The body heating and cooling media operate independently, and the temperature can be independently controlled; the cavity sleeve lined with wear-resistant alloy material has a long service life.

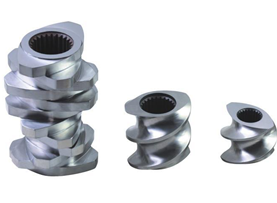

Screw and thread section:

The screw is a building block structure, and the screw can be combined arbitrarily to suit different formulas and product requirements; the screw and screw are made of high-strength, high wear-resistant special alloy material; the screw adopts the principle of full meshing model, three-dimensional design, and CNC machining. Not only the matching precision is high, the components are interchangeable, but the surface is smooth and self-cleaning.

Rotary cutting system:

The spiral rod adopts the principle of full meshing model, three-dimensional design, and numerical control processing. It not only has high matching accuracy, strong interchangeability of components, but also has a smooth surface and good self-cleaning. With independent safety switch and proximity switch, it is safe and reliable.

Liquid feeding and adding system:

The liquid feeder can be added separately from the corresponding position on the extrusion cavity according to the process requirements. The liquid feed volume can be arbitrarily set at 5%~200% of the solid feed volume. It is adjusted by the frequency converter, and the flow is stable and reliable; auxiliary materials (Such as: chocolate, butter, flavors and fragrances, etc.) The addition ratio is based on the liquid feed amount, set on the operation screen, and add in proportion.