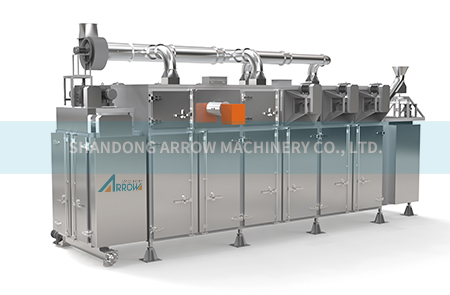

Features:

1. Material conveying adopts vibrating tray. During the material transmission process, the material is always in a state of turning, which can make the product evenly heated, can evenly bake the material, and maintain a good baking flavor.

2. Two-stage flame burner with strong temperature control ability.

3. High temperature resistant silicone sealing strip, good airtight and heat preservation performance, and strong anti-aging ability.

4. Circumfluence design, energy saving and high baking efficiency.

5 Through-flow ovens of different specifications and models can be selected according to the characteristics of the material.

6 Because the material conveying system uses stainless steel plates, it is hygienic and easy to clean.

7 The burner with dual stage fire can use natural gas and liquefied natural gas as raw materials.

8 During operation, the material vibrates up and down to ensure that the hot air is in uniform contact with the surface of the material, improve the efficiency of the hot air, reduce energy consumption, and the airflow can be recirculated to improve energy efficiency. The processing time can be shortened by 50% or more than ordinary systems.

9 The control system adopts touch screen control, using PLC temperature control and dual-stage burners, and an automatic temperature control system. Ensure the accuracy of temperature control and stabilize product quality. The touch screen interface is equipped with a monitoring interface, which can monitor the operation of the machine in real time.

10 Built-in hundreds of small air ducts directly impact the surface of the material with hot air. The impact technology is to use high-speed air perpendicular to the surface of the product to produce “impact” on the surface of the product. The purpose is to break the hot air boundary layer on the surface of the product. And the turbulence generated on the surface of the product, thereby increasing the transfer rate of heat and mass. Compared with the traditional convection and through-flow air flow, the impingement heating transfer rate is usually 2.5 times to 3 times, and the impingement technology is most suitable for higher surface area and volume ratios. Products. The large area of the product is conducive to heat conduction, and the smallest thickness is conducive to heat diffusion and dehumidification. We also provide a variety of steel mesh belts, continuous belts and hinged plate conveyor belt equipment.

Function: high temperature baking

Application products: high-temperature baking products

Burner model: BTG28P (0.18kw fan, air consumption 8-28m³/h)×2

Fuel consumption: 16-26kg/h

Total power: 30 (total fan power) + 5.5 (transmission motor) = 35.5kw

Size: 7000×5000×4100

Drying time: 50s

Vibrating bucket width: 600

Material layer thickness: single layer arrangement

Working temperature: around 200℃

Processing capacity: 300-400kg