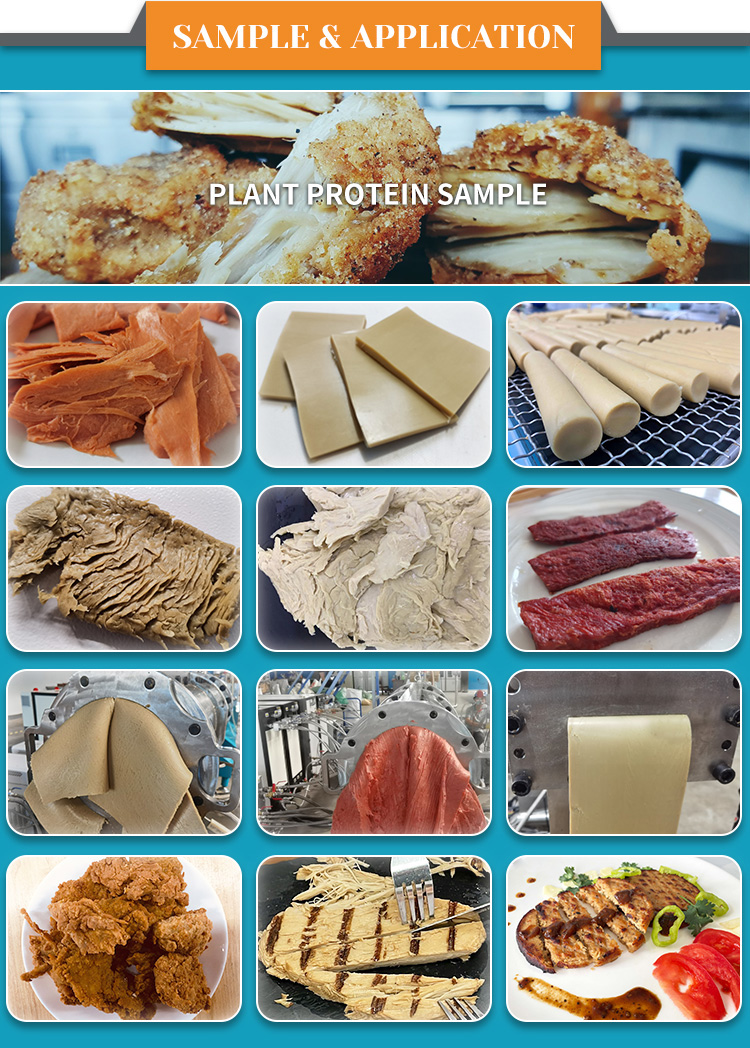

This process line is developed and manufactured on base of our experience combined with the advanced machines from foreign countries.This line takes defatted soyabean meal and peanut meal as main raw materials.After mixing,extruding,cutting and drying,the meal becomes layer fiber texture.The finish products have high protein;look and taste like meat;easy to absorbing oil,water and flavor;without cholesterol and animal fat,so it is widely used in meat products industry,fast food production frozen food production,and all kinds of vegetarian snacks and food.

Product Description:Use Soya pea, etc plant type protein as main materials , after extruded, finished product with good water absorption Fiber Extensibility. So far best substitution for animal meat, free cholesterol, high protein. Widely used at vegetarian client fast freezing food, sausage food.

Capacity: 10-300kg/h, 100-150kg/h, 200-450kg/h, 500-600kg/h, 600-700kg/h , 800-1000kg/h

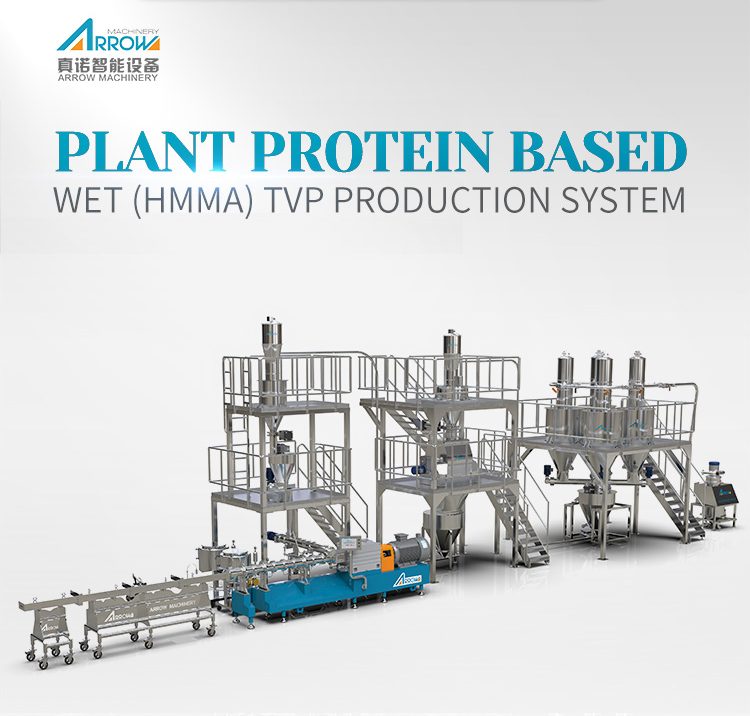

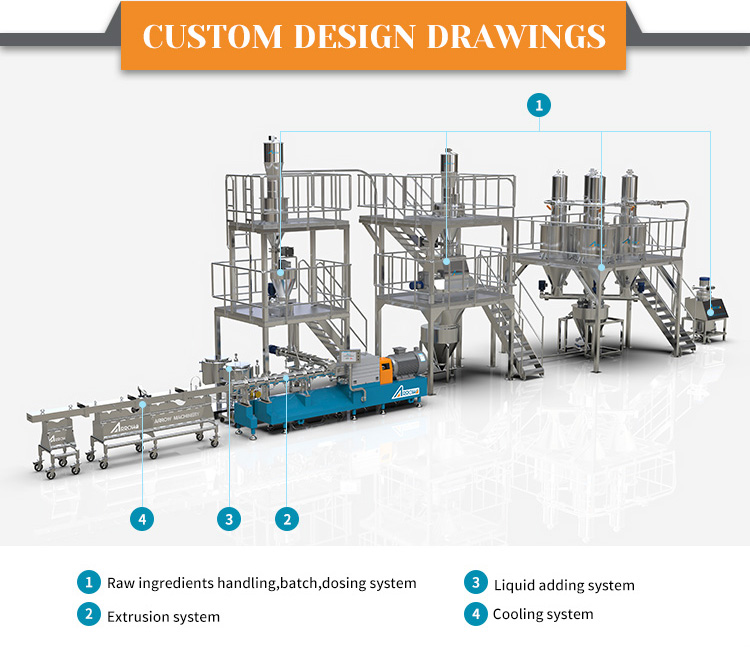

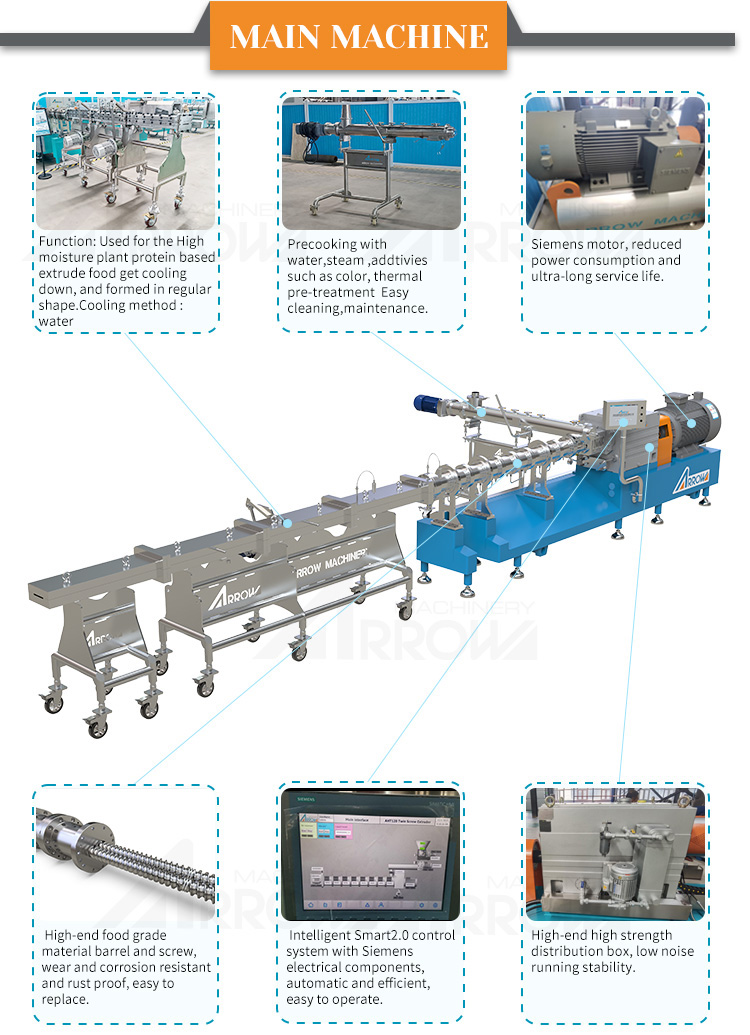

Plant Protein Based Wet (Hmma) Tvp Production System

Different normal type dry protein food, With its high moisture content,firm taste and good elasticity, high-moisture protein has become the best raw material to replace meat products. It is suitable for processing plant burgers,meat patties, chicken nuggets and other products.

Plant Protein Based Wet (Hmma) Tvp Production System